- +86-13646402382

- info@jnruijie.com

Model | 1390A |

Working Size | 1300mm*900mm |

Laser Type | DC glass laser tube (Co2) |

Wavelength | 10.6um |

Laser Power | 60W Co2 Laser Machine,80W Co2 Laser Machine,130W Co2 Laser Machine,150W Co2 Laser Machine |

Engraving Speed | 0-1200 mm/s |

Cutting Speed | 0-600mm/s |

Reposition Accuracy | ≤±0.01mm |

Cooling System | Water cooling system |

Control System | Digital Offline control system |

Supported Format and Software | PLT,DST,DXF,DWG,AL,LAS Support AutoCAD, Corel Draw output directly |

Motorized Up& Down Working Table | Ball Screw Transmission, Max Lifting 260mm |

Drive | Stepper motor |

Minimum Letter Size | Chinese:1.5mm English:1mm |

Working Voltage | AC 220V/110V ±10% 50HZ/60HZ |

Machine Power | ≤1500W |

Working Environment | Temperature: 0-45°C Humidity 5%-95% |

Laser Tube

The co2 laser cutting machine uses mature technology of Yongli/Reci light tube, which has reliable quality, and can make the co2 laser engraving machine run stably during engraving and cutting. The change of the spot output mode makes the co2 laser cnc machine cutting more accurate. And the service life of the machine laser co2 can be extended by at least 1-3 years.

Control System

The co2 laser engraving cutting machine adopts the digital offline control system, which can be connected to USB, RD and Lettro alternative, and has a friendly user interface, making the co2 laser engraver machine easy to master the operation.

Leadshine Stepper Motor

The efficient combination of Leadshine driver and stepper motor makes the co2 laser cutter machine run more stably and at higher speed, reduces noise and heat, and makes the processing accuracy of co2 laser machines more accurate. The adjustment-free function of our co2 laser engraving machines is your best choice to improve production efficiency and reduce maintenance.

U.S II-VI Optical Lenses

The laser co2 machine uses the American II-VI optical lens. With high light transmittance and extremely low optical distortion, it can effectively transmit the laser wavelength of the cnc co2 laser cutting machine. In a high temperature environment, it can also make the cnc co2 laser machine work stably for a long time. Reduce the maintenance co2 laser machine cost and increase the service life of the machine.

Double Work Platforms

Our best co2 laser machine has two worktables to choose from, one is an aluminum alloy blade worktable with durability and stability, which is suitable for heavier processing materials, has excellent heat dissipation performance, can reduce material reflection and scorching, and is easy to clean and maintain. The other is a honeycomb platform that supports light materials, fine engraving, and is less expensive.

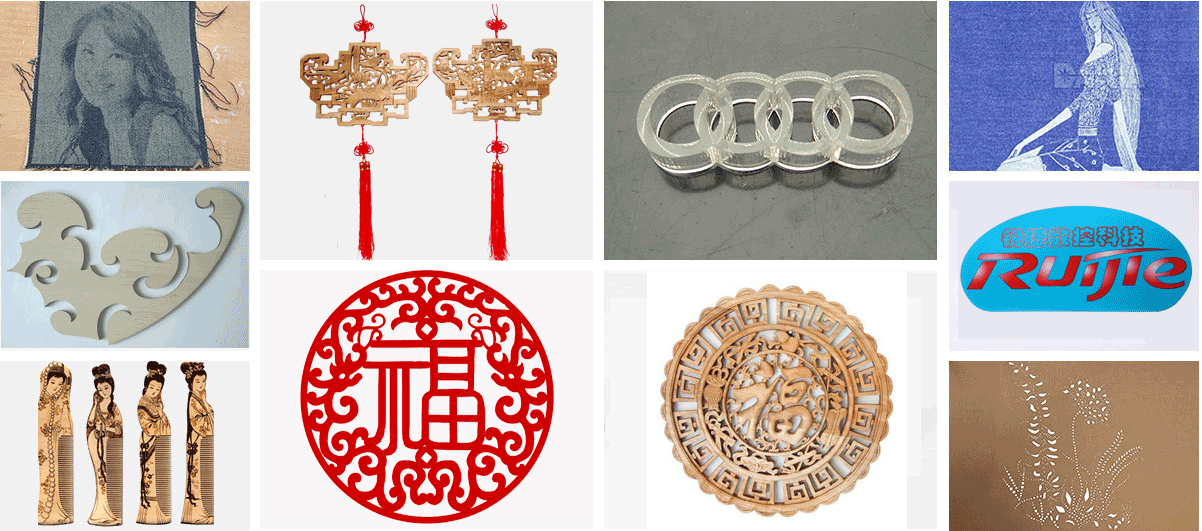

The co2 laser cutting and engraving machine can process a variety of non-metallic materials, such as wood (such as density board, solid wood, plywood, etc.), acrylic (plexiglass), paper, leather, rubber, cloth, glass, stone, ceramics, etc. Of course, different materials require adjustment of the power and frequency of the machine laser co2.If you want to get the co2 laser machine price, please fill in your requirements in the form below.