20000w Fiber Laser Cutting Machine in the Sheet Metal Processing Industry

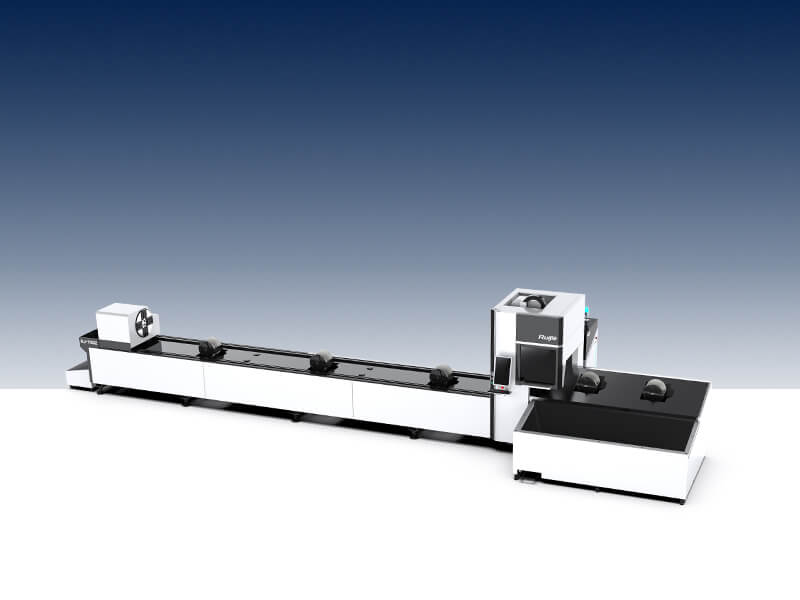

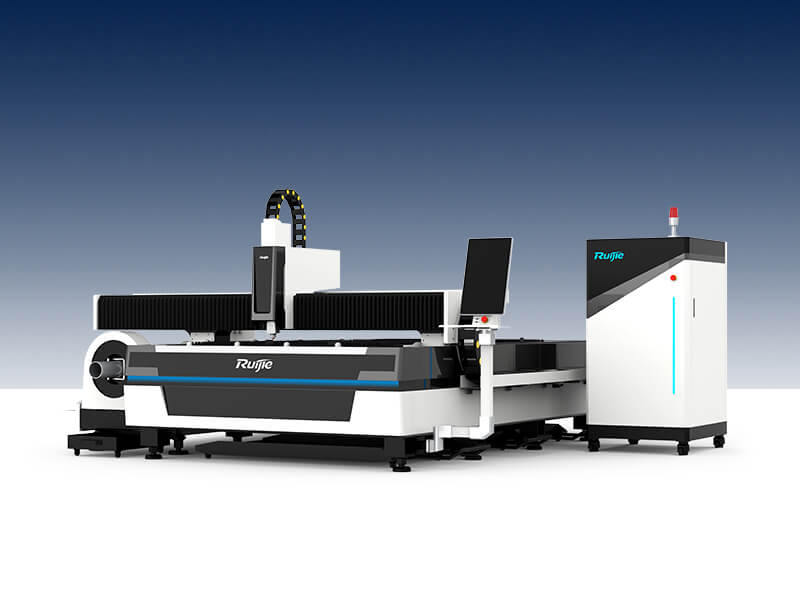

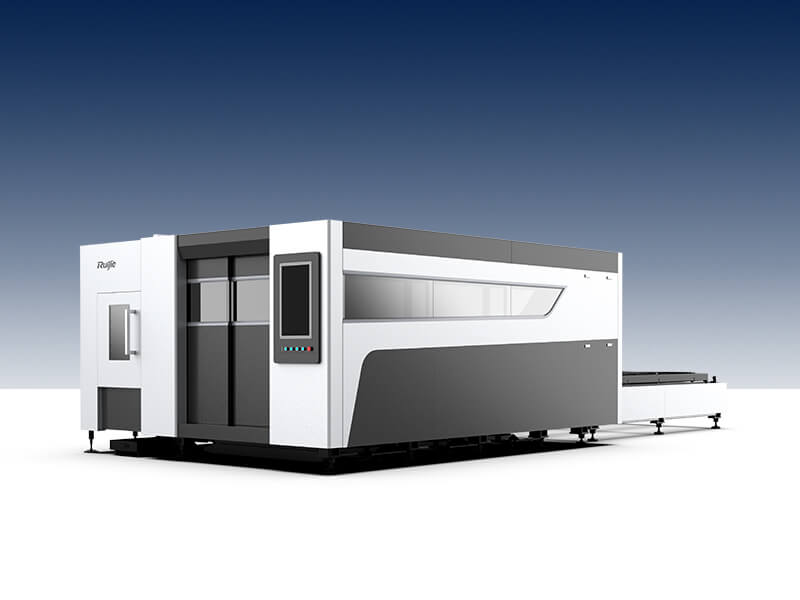

With the continuous improvement of processing accuracy and quantity, cost and efficiency are always a major problem in the sheet metal processing industry. How to find the balance point? How to reduce costs and increase production efficiency while ensuring product quality? Today, RUIJIE laser will show with you the advantages of 20000W fiber laser cutting machine in thick plate processing, and why choose RUIJIE laser as your business partner!

First, the work efficiency. If you want to maintain a greater competitive advantage in the industry,you’d better work with a higher cutting speed.The power 4000W or 6000W fiber laser cutter has been widely used in the sheet metal industry, there will a undoubtedly obvious advantage if you upgrading your equipment to 20000W,

Second, the cutting effect. Our machines are exported to more than 170 countries and regions around the world. Many customers have been introduced by old customers. The machine has good effects and good reputation. Many old customers have purchased machines many times.

Third, the after-sales service. RUIJIE laser have good after-sales service and worry-free purchase. RUIJIE has a professional after-sales team and engineers to provide professional face-to-face services to ensure the good operation of the purchased machine.

After using 20kw fiber laser cutting machine, not only greatly improved the cutting capacity and production, but the significantly improved cutting quality and equipment functions, and the cost of manual grinding is also reduced in the later stage. With the intelligent machine tool design and multiple function expansion, the workers will more comfortable and ease then using the machine, which meets the processing needs of a variety of mechanical parts.

All in all,any question about 20000w fiber laser cutting machine free to contact RUIJIE laser and send us email!