The Advantages of High Power Fiber Laser Cutting Machine

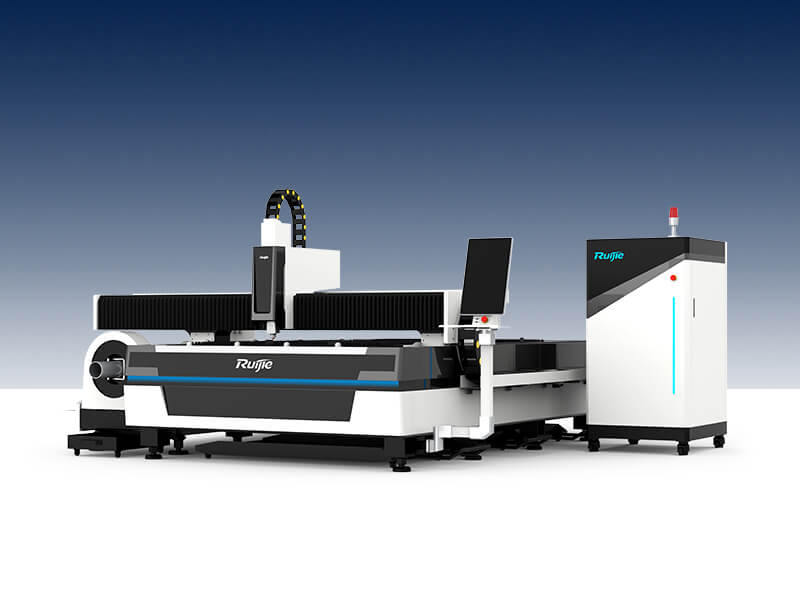

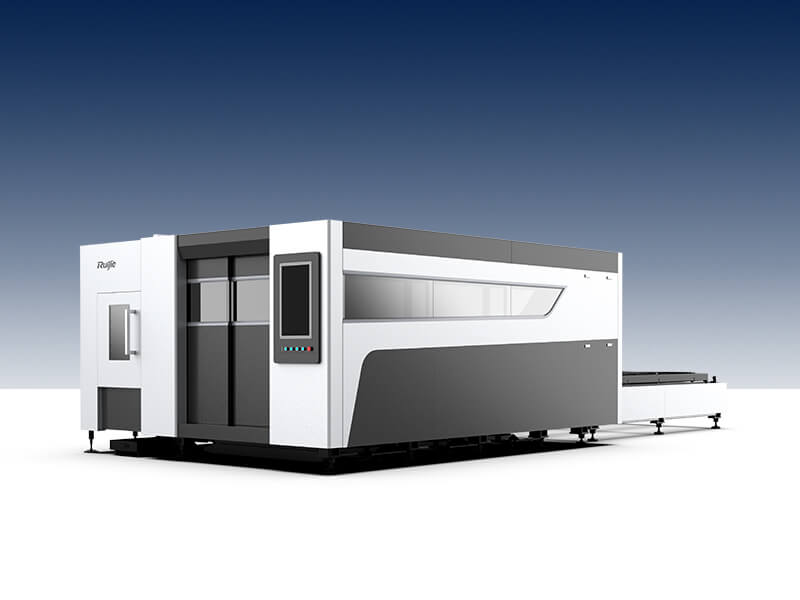

In recent years, high power fiber laser cutting machine is the mainstream development direction of laser cutting in the future. No matter from the perspective of market competition or user application direction, the growth rate of high-power fiber laser cutter is stronger year by year. High power laser metal cutting machine has become an ideal solution for sheet metal cutting industry because of its high efficiency, high energy density, non-contact processing and flexibility, as well as its advantages in precision, speed and efficiency. As a precision machining method, laser cutting can process almost all materials. It can be said that laser cutting machine has set off an important technological revolution in sheet metal processing industry.

Before 2016, the high power laser cutting market was occupied by 2kw-6kw. Today, 12kw, 15kw and 20kw have become the new favorite of the laser cutting market, and even 30kw-40kw laser cutters have been launched. Why the high power laser cutting machine become so popular? What are the advantages of high power fiber laser cutting technology compared with low power laser cutting?

At present, the thickness of aluminum alloy plate and stainless steel plate cut by high-power laser cutting machine can reach 40mm to 200mm or more respectively. With the continuous upgrading of high-power laser cutting machine technology, the thickness of cutting materials will continue to increase, and the price of processing thick plate will gradually decrease, so as to accelerate the application of high-power laser cutting machine in the field of thick plate.

Compared with the lower power laser, the improvement of cutting ability has a qualitative leap, so that the processing range of laser cutting machine has been greatly improved.

When choosing the power of laser cutting equipment, the cutting speed of different materials is the key factor. The application of fiber laser cutting in the processing of medium and low thickness plate has significant advantages. And the increase of speed brings the exponential increase of the economic benefits of fiber laser cutting machine.

In addition to the advantages of thicker and faster cutting, with the increase of laser power, laser cutting technology can play more tricks, such as the highly praised high-speed bright surface cutting technology.

HHB (high power, high speed, bright surface) is a kind of high speed cutting technology, which uses small nozzle, small air pressure and high power laser machine to cut carbon steel plates with different thickness under the condition of enough power, so as to obtain smooth cutting section and smaller machining taper. Smooth section for customers to follow-up processing. At the same time, the taper can be controlled below 0.2mm on both sides, which can better meet the requirements of customers in some high-precision processing industries.

In the actual operation, not only need to meet these conditions, but also need professional debugging, in order to achieve stable and consistent results.

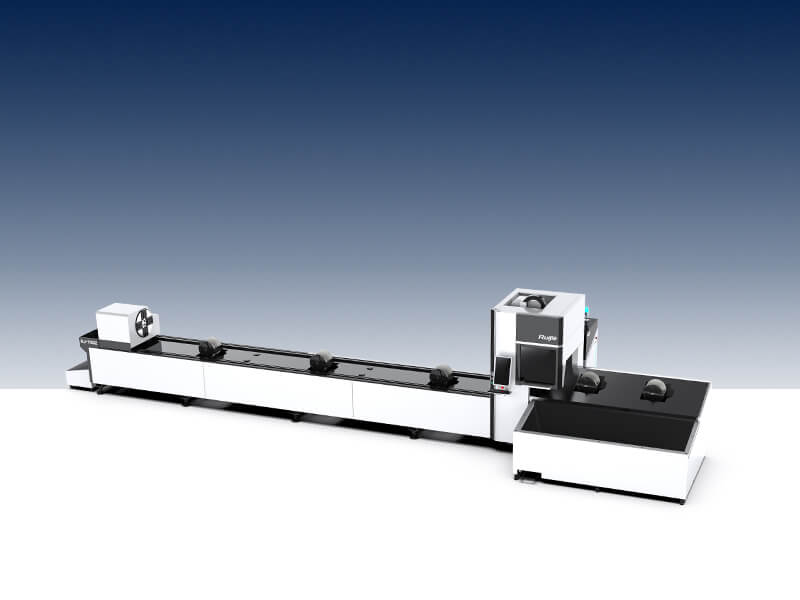

Fiber laser cutting machine as an ideal processing method, represents the development direction of modern metal processing technology. At present, high-power laser cutting machine is also toward high-speed, high-precision, large format, three-dimensional cutting and special material cutting and other fields of key technology research and development, so as to promote the development of high power laser cutting technology to meet the growing market demand.